Wet Exhaust System

Issues

By Cameron Sharpe — Seastar, 32-128,

Port Ludlow, WA

and Jim West — Kotuku, 32-197, Blaine, WA

Summary: This report

covers the investigation and potential solutions for

wet exhaust system leaks on Nordic Tugs manufactured

in the 1998 to 2002 time period. Due to continuous

product improvement by Nordic Tugs, the following may

apply only to the specific boats of the vintage covered

by the report.

From time to time, we've

read of the fiberglass reinforced pipe (FRP) in wet exhaust

systems cracking or leaking. When

we purchased our 1999 model Nordic Tug, Seastar (NT32-128

with a 220 HP Cummins 6BT5.9M), in December 2005, the

survey indicated seepage from the FRP section of the

wet exhaust system under the settee, just aft of the

90-degree elbow exiting the engine room.

In January 06, the shipyard wrapped

fiberglass mat around the leaking FRP section, halting

the seepage. Although

cracked and leaking FRP is often blamed on

over-tightening of the T-bolt connecting clamps, ours

was chemically bonded with no clamps. We soon discovered

another prominent failure cause.

At

the '07 Nordic Tug Rendezvous at Roach Harbor,

WA, Joe Franett, VP of Operations at Nordic Tug, came

aboard the Seastar to look over the area that had been

seeping. As we peeled back the insulation, we discovered

the fiberglass wrap was charred and the FRP was seeping

again. Joe suspected we were getting excessive

heating from engine exhaust gas, and suggested we gather

actual temperature data on the FRP. Joe advised

that 110° F was the target operating temperature

for FRP. He also advised us to review the exhaust

inspection and maintenance steps suggested in

the Tech Tips of Nordic Tug's newsletter "Waypoints

#11."

|

NME

wet exhaust water injection elbow showing

additional 18" lift. (Click to Enlarge Photo) |

Soon I was in contact with Jim

West and several other tuggers who had the same or

somewhat similar issues. Jim

and I (working on our respective boats) spent most of

the summer of '07 consulting with Cummins, Nordic,

National Marine Exhaust, Unicraft Marine Products (mufflers

and FRP) and Sherwood Pumps to gather technical and engineering

data. We also conducted many flow tests, spray

tests and sea trials to document what actually was happening. A

number of other tuggers contributed technical information,

shared their experiences and helped us locate resources.

First,

a short description of the typical wet exhaust system.

An engine-driven pump (1:1 ratio on the Cummins) passes

seawater through the transmission oil cooler, then

the engine heat exchanger and finally injects the water

into the hot exhaust gas from the turbocharger. The

water cools the exhaust gas from the 350-800° F

range to a much lower temperature that can be handled

by the FRP used in the exhaust system downstream. In

many cases, a water lift muffler is mounted

adjacent to the engine, achieving the same objective,

but taking up valuable engine room space. Briefly,

here's what we found.

-

|

Water

lift muffler typical of Nordic Tugs 42

(Click

to Enlarge Photo) |

Cracking and leaking of the

FRP wet exhaust pipe appears to be caused by hot

exhaust gas overheating the FRP (we measured operating

temperatures on the FRP from 245° F to 275° F). The

water injection elbow, with a proper hole-pattern

and adequate water flow, should quickly cool the

exhaust gas down to an operating range of around

110°

F. Depending on

the manufacturer and specific materials used, we have

been advised that the thin-wall FRP is generally rated

for 125° F continuous and 150° F intermittent.

Some newer types of FRP are rated as high as 200-350°

F continuous. Higher operating temperatures,

like those we measured, appear to bake the resin out

of the older type FRP, causing brittleness and pinhole

leaks.

-

The M71 Sherwood pump (#10615

impeller) used on our 220 HP Cummins 6BT5.9M engines

appears to be marginal for this application. It is

rated at 22 GPM at 2600 rpm, but only about 10 GPM

at 1200, and 11.8 GPM at 1400 RPM. Nordic used

a well-constructed National Marine Exhaust (NME)

wet exhaust elbow in many NT 32s, which rises about

18" higher than the original Cummins setup. This

provides improved surge protection from seawater

backing up into the turbocharger, as well as more

room in the engine compartment. But

it also adds 3/4 lb. additional head to a

marginal raw water supply.

-

The 90-degree elbow directing

the combined gas and water exhaust aft out of the

engine room creates spiral turbulence with hot spots

at the top of the pipe about every 18". The

hot exhaust gasses cool about 10° F each time

they pass the cooler raw water flow in the bottom

of the pipe.

-

|

Vetus

exhaust gas mixer |

On

Seastar, with a new impeller in a good pump, clean

intake strainer, clean engine heat exchanger, but

with about 10% obstruction in transmission cooler,

we measured 245° F on the top of the FRP just aft

of the engine room. Later, with the entire

system squeaky clean, temperatures dropped to 182°

F which was still way over the desired temp of 110°

F.

-

Adding a Vetus Injection Water

Mixer just aft of the 90 degree elbow leading from

the engine room, and some improvements on the NME

water spray nozzle design cooled NT32-128 Seastar's

hotspot to 105° F at 1200 to 1800 RPM, and no

more than 118° F during an extended run at 2200

RPM with 750° F Turbo outlet temp.

-

In Jim West's tug

Kotuku, NT32-197, a spiral water discharge nozzle

was added to the wet exhaust elbow itself with impressive

results, but he still has some work left to achieve

the desired temps in the FRP portion of the system.

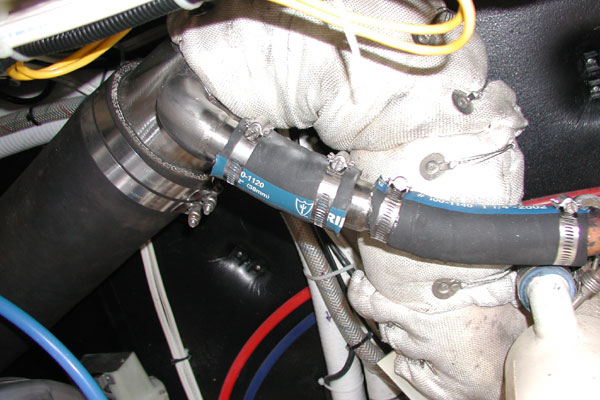

|

Spiral

water discharge nozzle on Kotuku

(Click to Enlarge

Photo) |

Conclusions: It

appears that the original design specific to our boats,

with: a) the small Sherwood M71 raw water pump and;

b) the increased height of NME Wet Exhaust elbow and;

c) the water injection spray pattern used at that time

led to inadequate

cooling of the exhaust gas before it entered the FRP

section of the wet exhaust system. The result was overheating

and ultimately leaking of the FRP, often near the T-bolt

clamps. The initial Cummins design appears to be at the

upper limit of the M71 Sherwood pump's capacity

when used with the stock Cummins water injection setup. Adding

the 18" of additional lift with the NME Water Injection

Elbow, results in 3/4" of extra head to the

raw water system. The turbulence issue downstream

of the 90 degree elbow going aft from the engine room

exacerbated the problem. (Current designs are very

good, and are well documented by NT during sea trials.)

|

Tirdent

VHT high-temp silicone hose on Seastar

(Click

to Enlarge Photo) |

Adding

a Vetus Injection Water Mixer appears to be a simple

and inexpensive solution for the 220HP Cummins application.

(http://www.fisheriessupply.com/online/ Go

to Products, search "Vetus" then to page

8.) Also for the Seastar we substituted Trident

VHT high-temp (350° continuous) silicone hose in

place of the FRP in this area as insurance. (Some other

brands of pipe also now meet this high temperature rating.)

It is also important to configure the water spray nozzles

in the wet exhaust riser to provide a larger number of

smaller streams, concentrating them at the top of the

turbo outlet (hottest exhaust area) to improve heat transfer. For Seastar, we are currently

working on a complete water pump upgrade package to

add the GC5 pump with #15000 impeller. The larger pump adds 33% more capacity

(and opens a host of additional engineering and cost

issues). If you already have the larger pump with

the 15,000 impeller, you probably don't have the

cooling problem. We are also working on a more

extensive report with upgrade part numbers, flow charts,

test data, photos, and discussion of the additional engineering

issues dealing with the pump upgrade. We will post

on this forum when the upgrade package is ready.

For questions for comments, the author

may be contacted at: SharpeC@cox.net

Readers'

Feedback:

Date: January 10, 2008

From: Bob Bevins — NT32-009, Anacortes, WA

After reading the report I have the

following suggestion:

Remove any rise in the exhaust

system and put a vertical loop in the exhaust just

before it discharges

overboard. This keeps a small amount of water

in the exhaust (FRP) section and aids in the cooling. The

loop also prevents water from going into the exhaust

system in a following sea.

My tug has had the loop in the exhaust for the past

twenty years and I have not had any issue with the

FRP getting hot.

|